All-over printing can make a regular tshirt a hugely impactful one with the right approach. There are 5 common mistakes made by folks when ordering all-over screen printing. These are hard learned lessons by textile screen printers. Read on to find out what they are, and how to avoid them.

All-over printing can make a regular tshirt a hugely impactful one with the right approach. There are 5 common mistakes made by folks when ordering all-over screen printing. These are hard learned lessons by textile screen printers. Read on to find out what they are, and how to avoid them.

Top 5 Mistakes When Ordering All-Over Screenprinting

- Disregard quality warnings.

- Sample only one size.

- Choose the wrong garment.

- Designs with large fill areas.

- Designs with tight registration.

- Other Options For All Over Garments

Disregard Quality Warnings

Collars, seams & natural folds do not lay perfectly flat on the table used for all-over screen printing. This is shown below by a pressman loading a tshirt on an all-over press.

Printing over seams, collars and folds results in printing imperfections in those areas. This is an acceptable part of the all-over screen printing process and is an important point regarding quality that your client should be aware of. The pictures below show some of the misprinting that can occur, however the final results can be more or less noticeable.

How to avoid a finish product that looks misprinted? Distressed artwork or loose designs do well to hide these print imperfections. Clever designs can avoid these tricky print areas altogether. Stunning all-over prints come an intentional combination of art and garment elements.

Sample Only 1 Size

All-over prints can look very different if you are printing on XS-3X. Virtual mocks ups can give you an idea, but if you are ordering samples, consider sampling on a few sizes to get a better feel for the look across the sizes on the order.

Regardless of how many samples you send to your client, it's a great idea to keep some AOP samples on hand for your own reference.

All-over plus designs are often a solution to avoiding multiple set-ups while maximizing all-over print capabilities.

Choose The Wrong Garment

Ever wonder how the print doesn't end up on the inside of the back of the shirt, by the collar?

Discs can be inserted in the collar for standard tshirt cuts: unisex tees, ladies and youth tshirts as well.

But, what about a garment like this?

The unstructured nature and wide arm cut-outs make it near impossible to keep the printing off of the inside front of the garment. All-over prints on the back of this garments will not produce good quality. Avoid garments with unsewn or roughly cut hems. The edges of the garment can curl onto wet ink!

Designs With Large Fill Areas

Shirts printed with large fill areas can be uncomfortable to wear if printed using regular plastisol ink. There are a number of approaches to soft-hand printing, but it's important to note that soft hand inks - including water based inks - don't feel super soft until they are washed. Off the press and out of the box, even soft-hand inks can feel off-putting. Be sure to let your client know the shirts will soften with washing.

All-over printed designs that use large fill areas are also especially prone to ink build up and misprinting around collars & seams and due to natural folds. In the photo below, you can see 2 very large and noticeable misprinted areas.

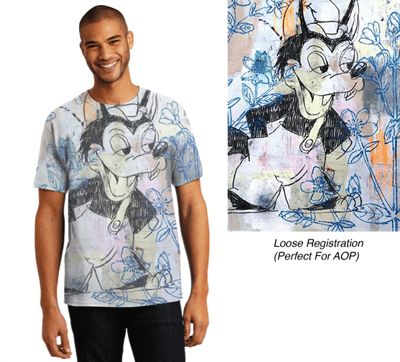

Designs With Tight Registration

In most cases, multi color artwork is not suited for all over screen printing. This is because the shirt moves a little between colors and the colors do not line up. A great example of multi-color art that will not work as AOP is this piece by Roy Lichtenstein. The style of design is considered tight registration.

The Lichtenstein artwork also uses large solid fill areas. Large solid fill areas show off any print imperfections due to seams, collars, and natural garment folds instead of hiding them.

Artwork that does not rely on colors printed with exact placement is considered relaxed or loose registration. A great example of multi-color art that will work as AOP is this piece by Word To Mother. The printed colors can shift around without being too noticeable and the illustrative style will hide any print imperfections that occur.

Other Options For All-Over Garments

Cut-and-sew can produce highest quality all-over screen printed garments without the collar/seam/fold quality issues. The fabric is screen printed as yardage then cut and sewn into shape. The presses are much different than the presses used for screen printing on apparel!

Dye sublimation is another process that can be used to create all-over printed t-shirts. For a high quality product, this process requires fabric printing before garment assembly, as well.

Leave a Reply

Your email address will remain private and will not be shared.