All Over Printing

About All-Over Printing

All-over printing (AOP) is done using much larger screens and specialized presses than our standard equipment. For one-color prints, we use the "One-Armed Bandit," which accommodates screens up to 42" x 34". For multi-color jobs, we use the larger "Alpha 8" press with screens measuring 39" x 28". Please note, jobs on the Alpha 8 require a minimum of 300 pieces.

Due to the nature of all-over printing, slight imperfections may occur, especially around the neck, seams, and armpits. We consider up to ½" registration variation acceptable in areas where full printing contact isn’t possible. Additionally, garment creases can cause unprinted spots. Because of these factors, we cannot guarantee perfect printing over seams.

How All Over Printing Is Different From Standard Screen Printing

The key difference between standard screen printing and all-over printing lies in the spray-tack application and how the shirts are prepared for the press. For standard designs, a light dusting of spray tack is applied to the press pallet, and the shirt is opened, pulled over the pallet, and smoothed flat. This prevents the shirt from shifting between colors during printing.

All-over designs, however, require a slightly different approach. Shirts are laid flat on tables, and a starch mixture is dusted inside using a separate machine. They are then placed on stiff cardboard sheets and smoothed, which makes it easier to load and unload the oversized pallets while keeping the shirts perfectly flat and minimizing registration issues.

All Over Printing Quality Guidelines

There’s no doubt all-over printing is awesome. The ability to print anywhere on the shirt is really a liberating aspect for designers, consumers, and vendors alike. It is important to be aware how the quality of these prints differ from screen prints created with a standard press.

Printing over the collar and shoulder seams is really popular, especially with retail inspired designs. If you lay a shirt down flat, you’ll notice how it is not smooth and flat in these areas. For this reason, when the squeegee passes over collars and seams, the ink is not applied smoothly. In these areas, ink has a tendency to skip or pool. This is completely acceptable and expected.

Since the coverage area on all-over prints is so great, we use soft-hand inks. Primarily, we use chino and fashion soft bases. Water-based and/or discharge inks can be used but there are drawbacks to those inks and they do not work with all designs.

The spoilage rate is greater than with standard screen printing. Expect a spoilage rate of 5%-8%. The process is so variable that many more shirts are considered “misprinted”. Of course, we return any defeats to the customer and they can do with them as they please.

Top All-Over Printing Articles

3 All-Over Printing Approaches for Custom T-Shirts

7 Things to Consider When All-over T-shirt Printing for Your

3 Keys To A Successful All-Over Print Design

What to Know About All Over Printing (AOP)

A Sticky Trick for All-Over Printing

What to Consider When Designing All-Over Printed T-Shirts

[Infographic] One Color All Over Print Layering Technique Published

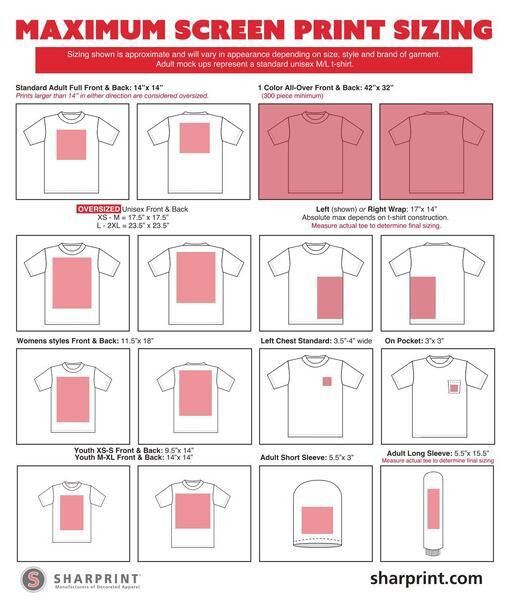

Maximum Screen Print Sizing

Take the guesswork out of creating the perfect all-over print. Our size guide gives you exact dimensions, layout tips, and best practices to ensure your artwork is production-ready. Download the guide now and set your designs up for flawless, full-coverage printing.