/SAAGNY-Header.png?width=600&name=SAAGNY-Header.png) All Over Prints (AOP) are some of the most exciting in the t-shirt screen printing world. And just like standard screen printing, a great all over print starts with great artwork. That said, the process for all over printing is different than the process for standard screen printing, so the kind of art that works is different too. In this article you'll learn how the processes differ and discover the 3 best art approaches for stunning all over prints.

All Over Prints (AOP) are some of the most exciting in the t-shirt screen printing world. And just like standard screen printing, a great all over print starts with great artwork. That said, the process for all over printing is different than the process for standard screen printing, so the kind of art that works is different too. In this article you'll learn how the processes differ and discover the 3 best art approaches for stunning all over prints.

The Printing Process: What You Need To Know

3 Art Styles That Work For AOP

The Printing Process: What You Need To Know

The main difference between all over printing and standard screen printing is how the garments are placed on a press to receive a print. When printing standard locations, t-shirts are loaded onto a press pallet. The pallet is sprayed with a light adhesive tack to stabilize the print area and provides a smooth surface for ink application. After loading a t-shirt, the pallet travels around the press, stopping at each ink color station to receive a print.

In the video above, you can see that the t-shirt sleeves and some of the t-shirt body falls off the side of the press pallet. In order to print all over a shirt, a much larger print surface is needed.

The video above shows a press that has a much larger print area so the entire shirt can lay on the pallet. There are two things to notice here:

1. While the printer is careful to smooth out the shirt, every inch of the shirt does not lay entirely flat.

2. Since the pallet is under the shirt instead of inside, the shirt will lift and move a little between each print color.

The press shown above is a dedicated machine for one color AOPs. Shirts are laid on a stiff cardboard carrier and placed under a screen. There is no press pallet on this machine.

How AOP Is Different From Standard Screen Print?

- Larger print size. all over prints can be as large as 42” x 34”.

- Unique presses. Specific presses must be used to accommodate the entire surface area of a t-shirt.

- Unstable print surface. Since the shirt is printed flat on itself, there is no stabilizing pallet behind the imprint area.

- Color placement shift. The shirt will move slightly after each print, so a white underbase or other print colors will not line up exactly.

Important Quality Information

Almost all AOP runs will have some degree of inconsistency. Collars, seams and natural folds in the garment are not smooth, flat imprint areas. Screenprints in these areas will be imperfect. Imperfections are unpredictable. Ink can continuously build up across a print run or be missing all together. Below are some examples.

The spoilage allowance for all over prints is 5%-8% depending on the design. Be sure to consult your decorator to determine how much overage to supply if exact quantities are needed. Note that the natural inconsistencies that occur over seams, collars, and fold may not be considered spoilage. Discuss the criteria for what is acceptable and what is spoilage with your decorator.

All Over Printing Quality Notes

- Expect print imperfections when printing over seams, collars, and shirt wrinkles.

- Portions of the design may be missing from affected areas.

- Ink may build up inconsistently.

- Artwork designed for AOP hides imperfections, but may not eliminate them.

- A higher rate of spoilage can be expected.

3 Art Styles That Work For AOP

The basic art requirements for AOP are the same as regular screen printing in terms of file size and format:

- Raster art files must have been created at a minimum of 150 dpi at the size the image will print.

- Vector art files should have all fonts converted to outlines or the font supplied separately.

- For designs using a mix of raster and vector components, supply the final file with support files included in their original format.

With this in mind, there are three styles of design that have proven to produce the best quality prints.

One Color Patterns

Illustrative and distressed artwork also work well as one color patterns. The irregular nature of these art styles hides naturally occurring print imperfections.

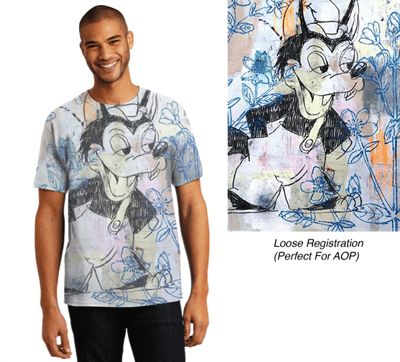

Multi-Color With Relaxed Registration

In most cases, multi color artwork is not suited for all over screen printing. As mentioned, the shirt will move slightly after each print color, so any artwork that relies on colors falling exactly next to each other doesn't work well as an AOP. A great example of multi-color art that will not work as AOP is this piece by Roy Lichtenstein. The style of design is considered tight registration.

The Lichtenstein artwork also uses large solid fill areas. Large solid fill areas show off any print imperfections due to seams, collars, and natural garment folds instead of hiding them.

Artwork that does not rely on colors printed with exact placement is considered relaxed or loose registration. A great example of multi-color art that will work as AOP is this piece by Word To Mother. The printed colors can shift around without being too noticeable and the illustrative style will hide any print imperfections that occur.

AOP Plus

AOP Plus

If you are interested in using a full color graphic as an all over print, but your graphic is tightly registered, AOP plus may be a solution. AOP plus incorporates a 1 color all over print with a second standard imprint location that can be printed in full color for maximum impact.

BONUS! Did you notice the printer in the first video is loading pre-printed shirts? He is adding a full front to a 1/c all over print for an AOP Plus. The t-shirt designs above also feature other specialty applications including high density, puff, and special effects clear.

Art Tips For Designing An all over Screen Print

- Avoid large fill areas.

- Print in tonal inks.

- Avoid printing light inks on darker colored t-shirts.

- Use illustration and distress instead of clean vectors.

- Avoid printing over seams & collars.

- Use designs with loosely registered colors.

- Consult your decorator and be prepared to make adjustments to the design for better printing.

There will always be imperfections when printing over seams, collars and folds. The secret to a fabulous all over print is hiding or minimizing the imperfections that occur.

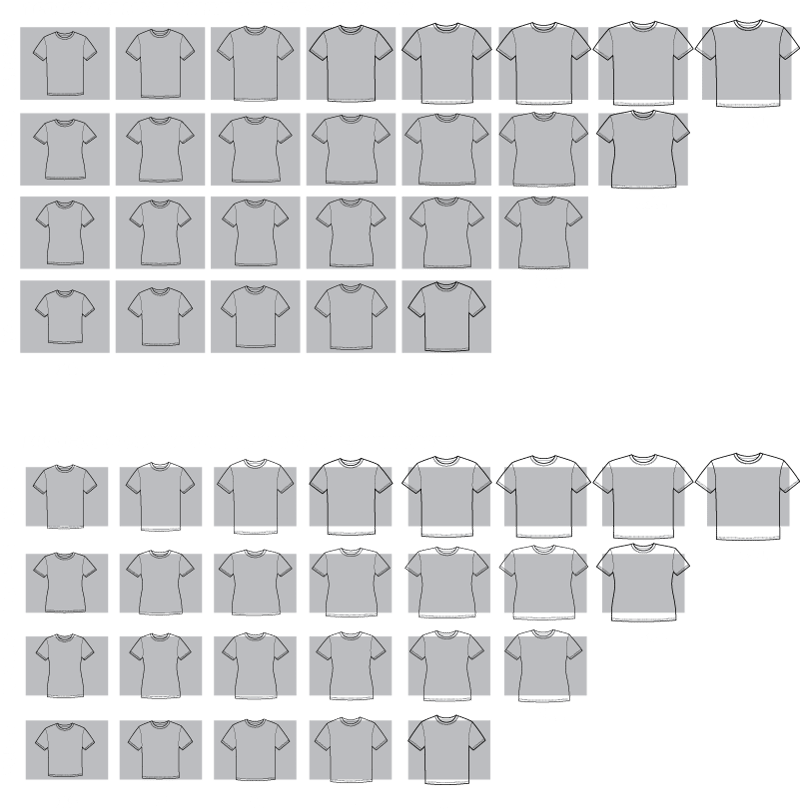

Maximum Print Sizes For AOP

Different presses have different maximum size capabilities and this should be taken into consideration when designing art for an all over print.

- Max size for 1 color AOPs: 42"w x 34"h

- Max size for multi-color AOPs: 39"w x 28"h

Using the chart below, you can visualize how the largest print size will look on various standard garments.

Research & Development

Sharprint conducts ongoing research and development with ink, press, and product manufacturers to offer the latest techniques in high quality screen printing including all over printing. Stay tuned for details about the upcoming release of the annual specialty decoration portfolio and sales too, Chicago Collection: The Neighborhood Collection.

Leave a Reply

Your email address will remain private and will not be shared.