You don't need to be a screenprint expert to order all-over printed t-shirts. With some key information on how to make all over print shirts, you can ensure the highest quality all-over screen printed product.

The Basics of All-Over Screenprinting is a handy reference that can be downloaded.

Great all over prints start with a tshirt design that works well with the screen print medium. Below are successful all over printed tshirt prints resulting from our process R&D.

Almost all AOP runs will have some degree of inconsistency. Collars, seams and natural folds in the garment are not smooth, flat imprint areas. Screenprints in these areas will be imperfect. Imperfections are unpredictable. Ink can continuously build up across a print run or be missing all together. Below are some examples.

The spoilage allowance for all over prints is 5%-8% depending on the design. Be sure to consult your decorator to determine how much overage to supply if exact quantities are needed. Note that the natural inconsistencies that occur over seams, collars, and folds may not be considered spoilage. Discuss the criteria for what is acceptable and what is spoilage with your decorator.

There are a number of considerations when you are ordering an all over print versus a regular screen print order. The main difference between all over printing and standard screen printing is how the garments are placed on a press to receive a print. When printing standard locations, t-shirts are loaded onto a press pallet. The pallet is sprayed with a light adhesive tack to stabilize the print area and provides a smooth surface for ink application. After loading a t-shirt, the pallet travels around the press, stopping at each ink color station to receive a print.

In the video above, you can see that the t-shirt sleeves and some of the t-shirt body falls off the side of the press pallet. In order to print all over a shirt, a much larger print surface is needed.

The video above shows a press that has a much larger print area so the entire shirt can lay on the pallet. There are two things to notice here:

1. While the printer is careful to smooth out the shirt, every inch of the shirt does not lay entirely flat.

2. Since the pallet is under the shirt instead of inside, the shirt will lift and move a little between each print color.

The press shown above is a dedicated machine for one color AOPs. Shirts are laid on a stiff cardboard carrier and placed under a screen. There is no press pallet on this machine.

The basic art requirements for AOP are the same as regular screen printing in terms of file size and format:

With this in mind, there are three styles of design for an all over print t shirt that have proven to produce the best quality prints.

Some of the most successful AOPs are single color patterns. Use a small company logo or iconic graphic element in a step-and-repeat pattern for a clean and simple AOP. Be sure to use enough spacing to avoid most seams and collars. Printing in tonal colors lessens the visibility of any print imperfections.

Illustrative and distressed artwork also work well as one color patterns. The irregular nature of these art styles hides naturally occurring print imperfections.

In most cases, multi color artwork is not suited for all over screen printing. As mentioned, the shirt will move slightly after each print color, so any artwork that relies on colors falling exactly next to each other doesn't work well as an AOP. A great example of multi-color art that will not work as AOP is this piece by Roy Lichtenstein. The style of design is considered tight registration.

The Lichtenstein artwork also uses large solid fill areas. Large solid fill areas show off any print imperfections due to seams, collars, and natural garment folds instead of hiding them.

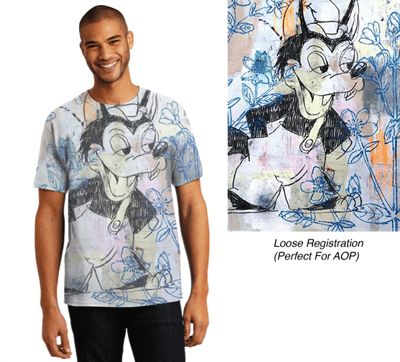

Artwork that does not rely on colors printed with exact placement is considered relaxed or loose registration. A great example of multi-color art that will work as AOP is this piece by Word To Mother. The printed colors can shift around without being too noticeable and the illustrative style will hide any print imperfections that occur.

AOP Plus

AOP PlusIf you are interested in using a full color graphic as an all over print, but your graphic is tightly registered, AOP plus may be a solution. AOP plus incorporates a 1 color all over print with a second standard imprint location that can be printed in full color for maximum impact.

BONUS! Did you notice the printer in the first video is loading pre-printed shirts? He is adding a full front to a 1/c all over print for an AOP Plus. The t-shirt designs above also feature other specialty applications including high density, puff, and special effects clear.

There will always be imperfections when printing over seams, collars and folds. The secret of how to make fabulous all over print shirts is hiding or minimizing the imperfections that occur.

Different presses have different maximum size capabilities and this should be taken into consideration when designing art for an all over print.

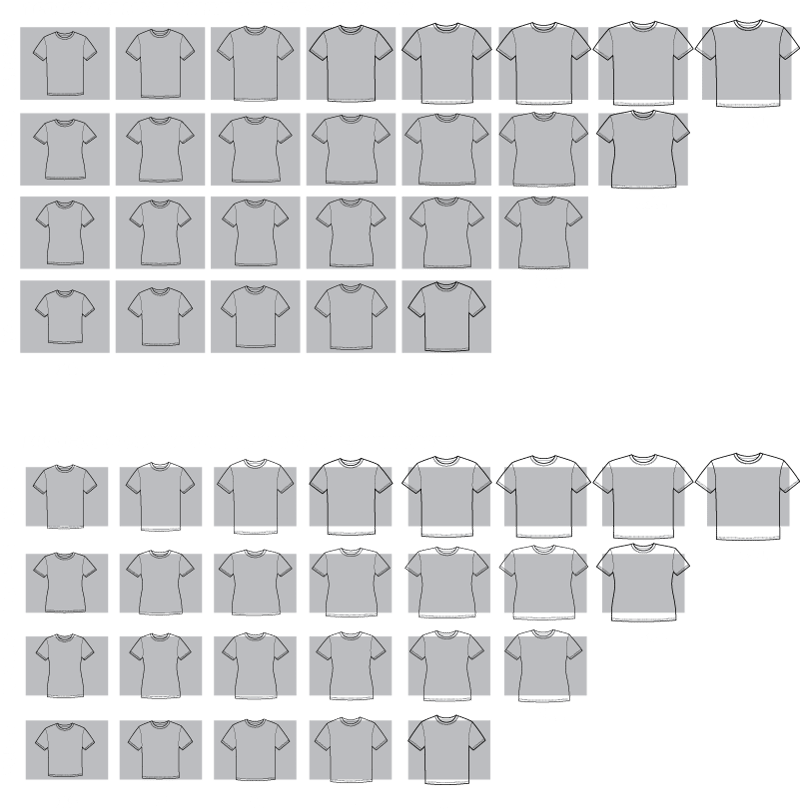

Using the chart below, you can visualize how the largest print size will look on various standard garments.

If you want to design an all over print t shirt smoother surfaces produce higher quality prints. For this reason, ringspun cotton or cotton with a high singles count are the most ideal. Regular cotton prints as well.

Use caution with polyester, poly blends, or dark fabrics. It isn’t possible to use a white underbase with AOP so ink colors may not appear as expected.

Any fabrics that are not typically screenprinted should be reviewed on a case-by-case basis.

More important than the fabric is the garment itself when it comes to all over printing. Garments must be relatively flat, smooth, and free of buttons, zippers, and sometimes pockets. all over screen printing cannot be done on hoods.

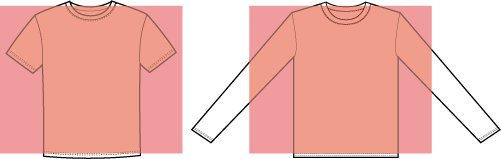

T-shirts and many tank tops are ideal for all over printing. Be wary of long sleeve t-shirts and crew neck fleece. When these garments are laid flat, the arms stretch out - they do not fall by the side of the body. The arms of long-sleeved garments will likely stretch outside of the print area.

Watch out for garments that have elastic waistbands or seams. You can see the folds created by the elastic waistband on the cheer shorts below. There would be a lot of print imperfection on this garment.

A soft-hand technique is typically the best choice for all over prints since they cover a large print area. The best soft-hand approach to use depends on the design, ink colors, and garment color. Consult your decorator for recommendations on the best ink to use on a per order basis.

Possible inks include:

Whether your design is one color or multi-color, it is not possible to line up an underbase when all over printing. If you are printing on dark colors, it may not be possible to achieve a Pantone match. Light ink colors may not be visible on garments of a darker color.

Polyester and poly blend garments require special inks to avoid dye migration. Use caution when printing on triblends, fleece, performance wear and other garments containing polyester.

For the best results, print darker ink colors on lighter garment colors. If printing on a dark color of garment, stick to opaque inks (typically pastel colors or greys).

Sharprint conducts ongoing research and development regarding how to make all over printed shirts with ink, press, and product manufacturers to offer the latest techniques in high quality screen printing.

Dye Sublimation is an alternative method to produce all over printed garments.

Cut-And-Sew is another option to produce all over printed garments.

You don’t need to know how to set up a screen print press to design or order all-over screenprinting on apparel. That said a bit of knowledge on the subject can help you make informed decisions to achieve the highest quality print.

Simply fill out the form to download the guide.