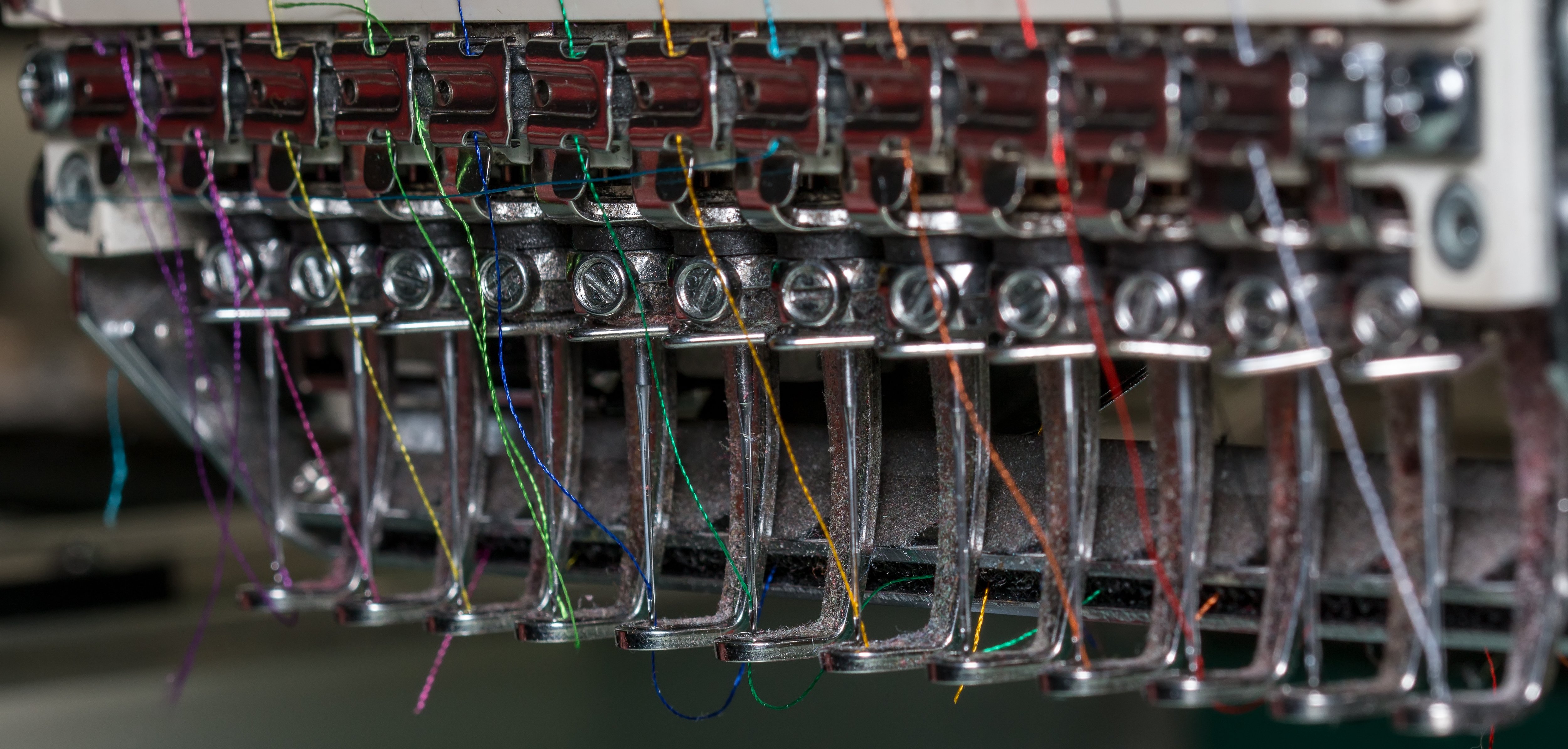

Embroidery Backing - A World of Options

Nothing can enhance or ruin embroidery more than what backing your decorator chooses to use. Here are some tips and things you should know about embroidery backings before making an apparel order.

Backings serve to “stabilize” the garment while it is being embroidered. They are placed behind where the stitching will go on a fabric to prevent the fabric from being squeezed, pinched, or bunched. Without backing, the precision needed for embroidery would not be possible and finished products would look “mushy” and lack detail.

There are two major types of backings: cutaway and tearaway in addition to some specialty backings for specific products. The fabric you are using and the design that you are stitching will decide what backing is best. Read on to learn the basics of backing.

Cutaway Backing

The big, tough kid on the block, cutaway backing provides great stability for an embroidery design. The name for this type of backing comes from the fact that a piece of backing larger than the design is placed behind the design and after stitching is complete, the backing is “cut away” from the underside of the fabric.

Cutaway backing is an excellent choice for sweatshirts, t-shirts, and other stretchier materials. Because these materials tend to shift during the stitching process, a stronger backing is required to provide the stability needed for a desirable looking finished product.

Tearaway Backing

Stitching less densely colored and detailed designs on more stable materials like denim allows for the use of tearaway backing. This backing is literally torn away from the design on the back of the material after the stitching is done. It provides a clean look on the back of the stitching, is less bulky, and generally cheaper to use. Of course, this means that the backing provides less stability to the stitching process and can affect the outcome of the finished product.

Tearaway backings are the most commonly used backing in embroidery because of its ease of use and clean look on the back of the material after switching. Remember though, not every tearaway backing is created equal. It’s important to work with your embroiderer to find the best tearaway backing for your project.

Other Backings

Solvy backing is a great backing for popular fleece products such as pullovers and blankets. Using solvy backing, the tables are turned a bit and the backing is actually placed on top of the fabric rather than behind it. This is done so that the embroidery does not sink into the material. After stitching is complete, the product is not even visible, resulting in a clean, sharp look.

No-Show backing, used for very sheer, delicate, and light colored fabrics is another specialty backing but keep in mind, it lacks the stability of even tearaway backing and should be used with mostly light, open designs that are not stitch heavy.

A Final Thought

Backings can make or break a design. It’s important to see the final product with your material/stitching/backing combination before starting production on your project. Working with your printer to ensure the right backing is used with the right material is crucial to having designs that look great and provide the exposure that you want for years to come.

Leave a Reply

Your email address will remain private and will not be shared.